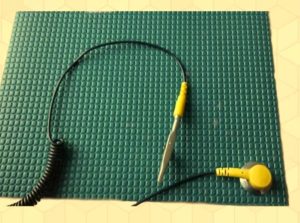

Preliminary preparation

Before taking out the received electronic components for quality inspection, anti-static workbench and mat can prevent static electricity from damaging the components. Workers are required to wear anti-static clothing when touching components to avoid static electricity.

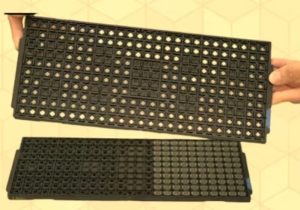

Products

Open the tray, use a vacuum pen to remove the chip or take out the tape-packed components from the anti-static bag. After quality inspection, cover the tray or use a new anti-static bag to pack the components.

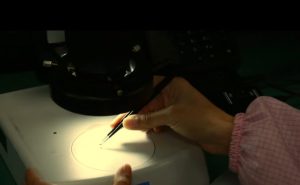

Inspection

Our QC inspection ensures that all packaging, labels and components conform with the original manufacturer specifications. Furthermore, our 200x magnification process helps ensure factory original condition of each component.

X-Ray Testing

With the efficiency use of state of the art x-ray testing, we inspect the internal dye to verify the authenticity of the component. Hence, we help to ensure that all components are original and consistent with the original manufacturer specifications.

Storage

Use nitrogen cabinet to dry and store components. Components that are damp need to be baked in industrial MSD component baking cabinet at high temperature of 110 degrees or low temperature of 45 degrees to help dehumidify the components.